What is electrophoresis?

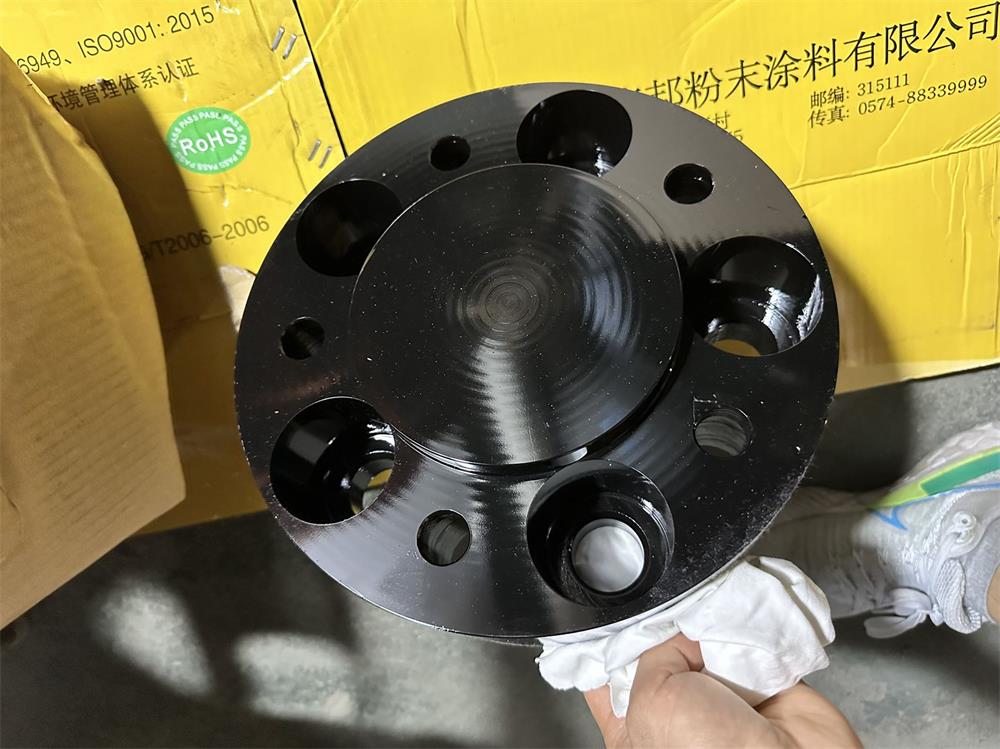

Electrophoresis is a process in which a metal surface has another resin ion deposited on the surface. The phenomenon in which charged particles (ions) in a solution move in an electric field.

What is electroplating?

Electroplating is the deposition of polymer resin on the metal surface. The process of plating a thin layer of other metals or alloys on certain metal surfaces using the principle of electrolysis.

Advantages of Each Process

Electrophoresis

The advantage of electrophoresis is high imitation plating, but there is still a certain gap in performance and color. It is difficult to achieve the metallic texture of electroplating with electrophoresis. However, in terms of paint film uniformity, the film thickness of the electrophoretic paint coating at high and low potentials is uniform, while the high and low potential coatings of the electroplating layer are uneven.

Electroplating

Electroplating is a process that uses electrolysis to attach a metal film to the surface of metal or other material parts. The advantage is to prevent metal oxidation (such as rust) and improve wear resistance, conductivity, reflectivity, and corrosion resistance (sulfuric acid). Copper, etc.) and improve the appearance and other effects. Electroplating has a metallic feel.

Therefore, the industrial aluminum profile electrophoresis process has more advantages in paint film coverage than the electroplating process. The electrophoretic coating can completely cover hidden areas, such as inner walls and depressions, while electroplating generally cannot deepen hidden areas.

Electrophoresis can only act on conductive metal surfaces. In addition to metal surfaces, electroplating can also be electroplated on specially treated plastics.

Cost Comparison of Electroplating and Electrophoresis

Electroplating is a layer of metal plated, while electrophoresis is coated with a layer of resin. Compared with electroplating, electrophoresis is simpler and more convenient to operate. Therefore, there is a huge difference in terms of cost budget. Electrophoresis is much cheaper than electroplating.

Environmental Protection of Electroplating and Electrophoresis

Electrophoretic paint uses water as the solvent, produces less waste, and causes less environmental pollution.

Electroplating wastewater contains heavy metal ions such as chromium, cadmium, nickel, silver, and cyanide, which can easily cause environmental pollution.