General

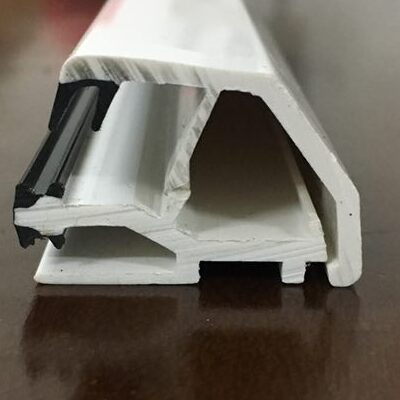

PVC foam profile refers to a type of building material made from polyvinyl chloride (PVC) that has been expanded and foamed to create a lightweight and durable product. PVC foam profiles are commonly used in various construction applications due to their versatility, cost-effectiveness, and favorable physical properties.

Manufacturing Process

PVC foam profiles are typically manufactured through an extrusion process. During this process, a PVC compound is heated and passed through an extruder, which incorporates a chemical blowing agent into the material. The blowing agent generates gas bubbles within the PVC, resulting in the expansion and foaming of the material. The foamed PVC is then shaped into profiles of different sizes and cross-sections, such as sheets, boards, or customized profiles.

Advantages

The foam structure of PVC foam profiles provides several advantages. It offers excellent insulation properties, both thermal and acoustic, making it suitable for applications where temperature or sound control is desired. PVC foam profiles also have a high strength-to-weight ratio, meaning they are lightweight yet strong and can withstand various loads and impacts. Additionally, PVC foam profiles are resistant to moisture, chemicals, and UV radiation, making them suitable for outdoor or wet environments.

Widely Application

Due to their versatility, PVC foam profiles find application in numerous industries. They are commonly used in construction for applications such as wall cladding, roofing, window frames, doors, and decorative moldings. PVC foam profiles are also utilized in the advertising and signage industry for creating displays, letters, and exhibition stands. Their ease of fabrication and installation, coupled with their durability and low maintenance requirements, contribute to their popularity in these sectors.

Environmental Consideration

It’s worth noting that while PVC foam profiles offer several advantages, there are also environmental considerations associated with PVC as a material. PVC is derived from fossil fuels and can release toxic fumes when burned. Additionally, its production involves the use of chemicals that can be harmful to human health and the environment. Therefore, it’s important to consider these factors and explore sustainable alternatives when appropriate.